- Capacitive Touch Sensor Design: 300kHz, 470pF

- Capacitive Sensor Circuit: Activate Shop Windows with This Design

- Build Your Simple One-Wire Touch Detector Circuit

- Build Your Own Touch Switch Circuit – 3.3M, 1N4007

- Capacitive Sensor Circuit: Build Your Shop-Window Animation

- Touch Activated Light Circuit: MOSFET vs. Transistor Design

Capacitive Touch Sensor Design: 300kHz, 470pF

Description

Capacitive touch sensors rely on the electrical capacitance generated by the human body. When, for example, a finger approaches the sensor, it establishes a capacitance with Earth, typically ranging from 30 to 100 pF. This effect can be utilized for proximity detection and touch-controlled switching. Capacitive switches offer distinct advantages over other switch types – such as those utilizing 50 Hz or 60 Hz detection or resistance detection – but they often present a more complex implementation.

Manufacturers like Microchip have historically produced specialized integrated circuits (ICs) for this application. However, it remains possible to design a reliable capacitive detector and/or switch utilizing a limited number of standard components. This design detects the alteration in the pulsewidth of the signal when the contact is made. In Figure 1, the following stages can be observed, proceeding from left to right: a square-wave generator operating at a frequency of 300 kHz, employing a Schmitt trigger integrated circuit (IC1 – CD4093); an RC network featuring a fly-back diode, followed by a Schmitt trigger/contact plate and an isolation capacitor with a value of 470 pF; and an RC network that converts the change in pulsewidth into a voltage.

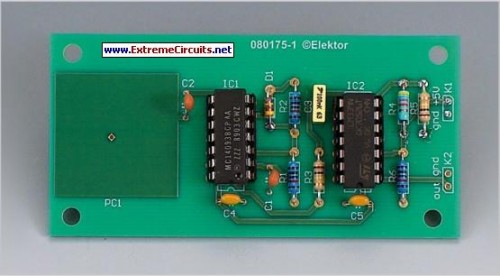

Picture of the project:

This voltage measures approximately 2.9 - 3.2 V when the plate is touched (and 2.6 V when it is not touched); an LM339 comparator is used to compare the voltage at point C with a reference voltage (D). This reference voltage is set to approximately 2.8 V using a potential divider formed by resistors R4 and R5. As long as the contact plate is in contact, the output of the circuit will be active. To illustrate the operation of the circuit, the signals at various points are shown in Figure 2. The dotted line represents the signal when the plate is touched, while the solid line represents the signal when it is not touched.

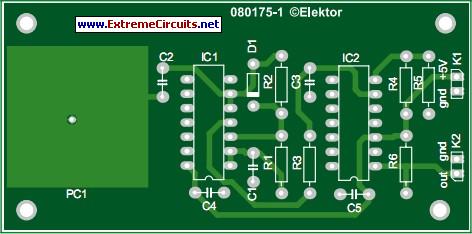

PCB layout:

The reference voltage at D must be established initially via the potential divider formed by R4 and R5. The required value is strongly dependent on the surface area of the contact plate (typically a few square centimeters). Larger surfaces increase the capacitance, and consequently, the voltage at C will be greater when the plate is not touched. Therefore, the reference voltage at D should be set closer to 3.4 V. This touch sensor can, therefore, also be made to function with larger areas – such as the complete metal enclosure of a device.

Circuit diagram:The circuit only operates when a connection for higher frequencies (300 kHz) is made to Earth in some way. Consequently, the circuit does not function in battery-powered systems without a connection to Earth. In many systems lacking a direct connection to Earth, sufficient parasitic capacitance to the mains Earth is present. In certain cases, it will be necessary to add an extra capacitor between the mains Earth and the Ground of the circuit. To comply with safety regulations, this capacitor should be rated for >3-4 kV (i.e., a Class Y capacitor). The output signal can be used in various ways to activate systems. The addition of an extra Schmitt trigger to the output is recommended in many cases, particularly if the output connects to a digital input.

COMPONENTS LIST

- R1,R2,R6 = 10kO

- R3,R5 = 100kO

- R4 = 47kO

- C1,C2 = 470pF

- C3,C4,C5 = 100nF

- D1 = 1N4148

- IC1 = CD4093

- IC2 = LM339D

- K1,K2 = 2-way pinheader

Downloads

The layout for the printed circuit board is available from the Elektor Electronics website as a free download; ref. 080175-1.zip.

circuit from http://www.extremecircuits.net/2010/05/simple-capacitive-touch-sensor.html